Author:

Stewart Berry

Images: Dan Martin

Where your facilities are placed and evaluating whether their placement is optimal are critical considerations for many organizations. While most of these tools are too expensive or complex to make such analysis easily accessible, these powerful analytics are provided as easy-to-use Wizards in Maptitude for only US$695 annually.

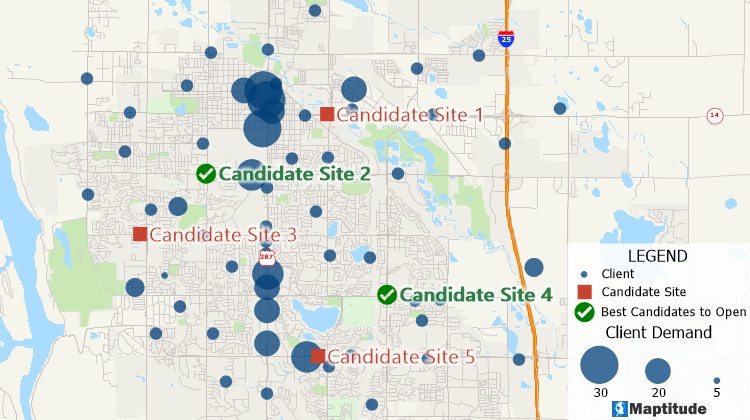

Supply chain greenfield analyses and brownfield analyses are variations of the facility location problem, where the goal is to locate one or more facilities. The locations for these facilities are chosen from a set of candidate locations. In a regional warehouse location problem, for example, you may have identified half a dozen parcels that you can acquire for a new facility; in a nationwide location problem you may have chosen 25 metropolitan areas as possible facility sites. Typically, there is also a set of existing facilities to be considered in evaluating new locations.

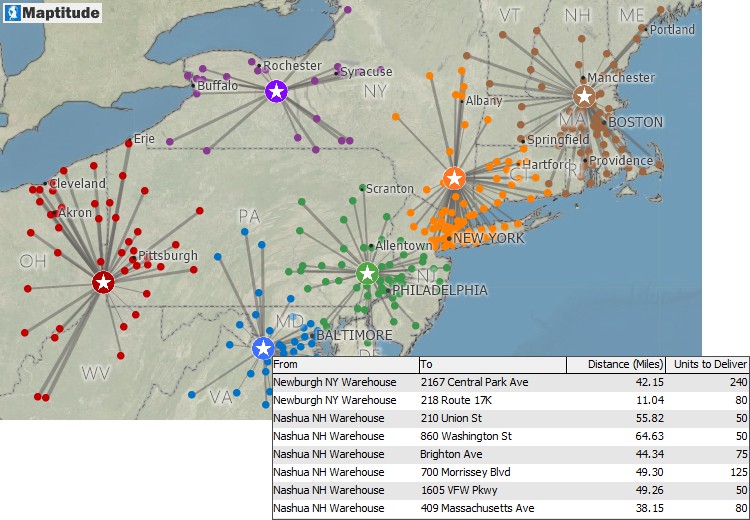

Each facility serves several clients. In some cases (e.g., delivery businesses) the clients are individuals or households, while in other cases (e.g., warehouses) the clients are stores or manufacturing facilities that are served by the facility. In some cases, a client may require more deliveries than another client located the same distance away. In this situation, you can apply a weight to apply more importance to the clients who require more deliveries.

Sometimes you may want to consider closing existing facilities as part of a facility location problem. In this case, you treat the facilities that might be closed as candidate facilities rather than as existing facilities. Maptitude then determines whether these facilities should be closed or kept in operation.

Facility location (or location-allocation) analysis determines the optimal locations for a given number of facilities from a set of possible locations based on some criteria while simultaneously assigning the customer demand to the stores or distribution centers. Generally, the goal is either to provide a high level of service, to minimize operating costs, or to maximize profits.

Facility location can be used where there is a need to determine the best location for a new:

The goal of solving a facility location problem may also be to determine the number of facilities that are required to guarantee a certain level of service, such as when there is a need to:

There may be financial or operational constraints that affect these problems, such as an upper limit on the number of facilities that can be added, or a fixed budget for adding such facilities. In other cases, revenues and profits depend on the choice of facility locations, and there is a trade-off between the costs of adding a facility with the potential revenue benefit. There are also facility location problems where the goal is to maximize the distance between facilities and the population they serve. Landfills and power plants, for example, are often located relatively far from major population centers. The locations of existing facilities will also affect the choice of locations, and a common situation involves both adding new facilities and closing existing facilities.

Organizations employ Greenfield Analysis (GFA or “center of gravity analysis”) to identify the ideal location and number of distribution facilities. GFA is widely utilized in supply chain planning since it assists businesses in making better strategic choices.

Greenfield analysis allows decision makers to quickly:

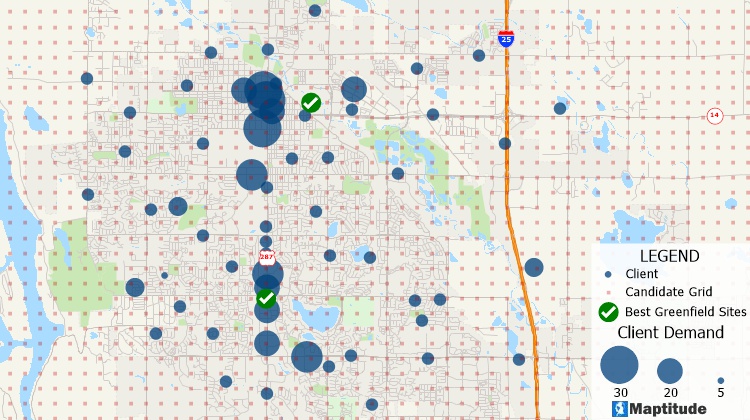

The Maptitude Facility Location tool is designed to help you pick sites when looking at opening a new facility and will identify the best locations. However, analysts frequently don’t have a list of “Candidate” facilities and would prefer to simply search for the best location in the target area. Such greenfield analysis uses a grid layer as a stand-in for the candidate facilities to perform this kind of ‘What If?’ analysis.

Greenfield analysis simplifies the facility location problem, only requiring:

This basic greenfield analysis simply uses “as the crow flies” distance, ignoring roads, cities, topography, etc. and just offers the simplest optimal solution. Maptitude will assess all the potential locations for building a new facility and will identify the sites that minimize the average distance from a client to a facility. This optimal point is called the center of gravity.

Below we explore more sophisticated variations of GFA that include greenfield analysis with roads, with pre-existing real estate locations, and brownfield analysis.

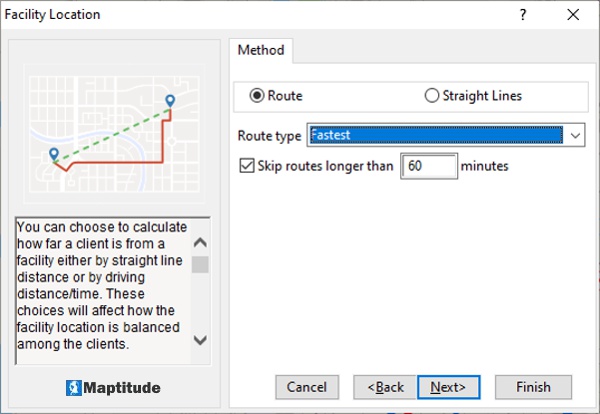

This type of greenfield analysis uses the same inputs as a standard GFA but is more realistic because it uses demographics and real road-based travel distances and times. You can choose between the shortest or fastest routes between your supply and demand locations with limits on how far destinations can be serviced.

This video shows how to run this facility location analysis in Maptitude:

Brownfield analysis (BFA) can suggest how many facilities you need to meet new demand, or which pre-existing locations should be retained for optimal performance. Brownfield analysis is used to restructure the supply chain or when growing or shrinking your existing distribution network, whereas Greenfield analysis is used to find the best locations for a pre-defined number of new warehouses or facilities.

Maptitude will calculate the ideal number of facilities to build, according to your constraints, and then find the best locations at which to build them. For example, your constraints may be based on:

When you already have an operational supply chain but need to restructure it, for example owing to the addition of new clients in remote places or mergers and acquisitions, brownfield analysis is a powerful tool.

In Maptitude you perform brownfield analysis, as described for GFA, but with inputs for the existing supply chain:

BFA will identify new facility locations along with which customers they would serve, supporting a quick, efficient, and realistic supply chain restructuring analysis.

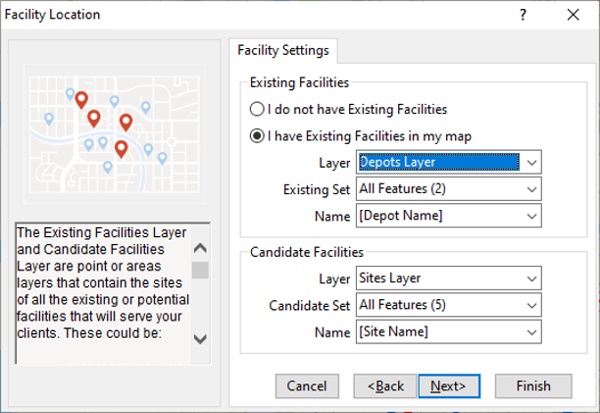

The Existing Facilities Layer and Candidate Facilities Layer are points or even areas (e.g., property parcels for facilities or ZIP Codes for demand by population) that contain the sites of all the existing or potential facilities and clients served. These could be:

The Existing Facilities map layer contains the facilities that are already built. The Candidate Facilities map layer contain potential site locations you have determined for your new facility/facilities. For both, you can use a subset or the entire map layer.

Greenfield and brownfield analyses are extremely useful tools for review of the supply chain structure and its future optimization. Using these tools in Maptitude, you can:

Looking for ways to create an optimal supply chain network? Start building your supply chain with Maptitude mapping software!

Maptitude lowers the burden required for performing greenfield analysis, brownfield analysis, and supply chain network optimization. While many factors go into managing facility networks, a mapping application such as Maptitude ensures that you maximize use of your time and are easily able to explain your findings to others. Maps are an intuitive way to convey and analyze large amounts of data. Maptitude can support all the above analytics and comes with all the data used in the examples shown, as well as information for almost any industry and sector you would need to map.

If you already have Maptitude, you can find step-by-step instructions for optimizing your supply chain network in the Maptitude Learning Portal.

Learn more about Maptitude to see how you and your team can use Maptitude to make informative and insightful maps!

Schedule a Free Personalized Demo

Home | Products | Contact | Secure Store